Material of Construction ( MOC):

The Storage tanks used in the chemical industry come in a wide array of models, types and materials..These include fiberglass tanks (FRP) and several varieties of polyethylene PE ( HDXLPE, HDPE, MDPE, LLDPE) and metal tanks. The metal tanks are one of the traditional material but because of its poor chemical resistance and corrosion resistance it has been replaced with plastic tanks for non pressure/ low pressure applications. The metal tanks are lined with rubber to increase its chemical resistance but these linings are non-permanent in nature and requires periodic replacement.

Amongst plastic tanks FRP are being used for quite some time with innovation in technology HDXLPE is replacing it for most of the application because of its inherent adantages.

FRP VS HDXLPE TANKS:

Both of these tank materials offer unique advantages over the wide range of important tank properties which include chemical compatibility, impact resistance, weatherability, cost, high temperature performance, pressurized applications, stress crack resistance, environmental friendliness, etc. In light of this wide diversity of performance characteristics, a comparative study of the benefits and features of each of these materials, especially in the storage of harsh chemicals, is appropriate.

Chemical Resistance: The selection criteria for the material from which the storage tank will be manufactured is, of course, dependent on the liquid being stored. FRP is the material of choice for the storage of hydrocarbon-based or petroleum-based chemicals, such as gasoline or kerosene. When the liquid being stored is an oxidizer, such as Sodium Hypochlorite or Sulfuric Acid, FRP has its limitations and drawbacks. Polyethylene tanks, especially cross linked Polyethylene tanks (XLPE) with an oxidation resistant liner material, provide superior chemical resistivity to oxidizing chemicals. Unlike FRP tanks, they have no chemical attack points, which readily combine chemically with the stored chemical. Furthermore, as the XLPE tanks have no reinforcement, there is no interface between the resin and the glass fiber, a location in all fiberglass tanks that is an inherently weak area and is highly susceptible to chemical attack. A major problem with the storage of oxidizing chemicals is the potential increase in the corrosive nature, chemical attack, or these liquids when they become contaminated. Unlike PE tanks, FRP tanks are susceptible to leaching of minor resin components by the action of these oxidative liquids. This contamination can have a direct effect on the final quality of the FRP tank. Delamination or cracking at the microscopic level, additional points of weakness or attack, can occur thus affecting the overall performance on the tank. PE tanks, especially XLPE with an oxidation resistant liner, do not delaminate nor do they have the tendency to crack at the micro level.

Mechanical Properties: FRP tanks tend to be stiffer than their plastic counterparts. This in turn allows the tanks to have decreased thickness for the same application, which makes them lighter. However, this benefit does not come without a price. The resistance to impact damage in FRP tanks are much less than PE tanks. The serious problem with impact damage in FRP tanks is made even worst by common variations in the manufacturing process. For instance, failure to maintain uniform thickness, failure to regard ambient conditions/dew point, failure to apply each layer within specified processing window, improper cure, use of partialy-curred resins and use of incompatible resin and fiber glass (sizing). These improper techniques can cause the tank to delaminate and crack, which in turn compromises the mechanical properties, especially strength, stiffness and impact resistance of the FRP tank. It’s interesting to note that the highest percentage of damage that occurs in FRP tanks is during loading/unloading from the manufacturer to the end use site.

Scratch Resistance: The scratch resistance of a tank is critical in high-end applications. The scratched areas are potential weak points that affect or compromise the overall performance of a tank. Plastic tanks such as PE tanks have a higher scratch resistance when compared to FRP tanks, that is, if they are scratched, the potential negative results are much less. The concern with FRP tanks is that when they are scratched they will delaminate because of infusion of the liquid along the fiberglass surfaces. As indicated earlier, any delimitation in the fiber glass layers creates a weak point that compromises the overall mechanical properties of the tank, as well as, make it more susceptible to chemical attack from external environmental conditions. Design Flexibility: The FRP process provides greater flexibility in the larger size and higher capacity (50,000 litre and higher), tank-manufacturing arena. Nevertheless, this process is limited when options such as molded-in fittings, ribs and stiffening design features, and non-conventional tank designs with undercuts are being considered. The rotomolding manufacturing process is inherently flexible due to its no pressure free material flow characteristics. This allows users to tailor make their tanks to fit the application. To illustrate this point further, fittings in FRP tank applications cannot be created during the winding/lay-up of the tank. Furthermore, the fittings must be a dissimilar material, which limits the applications since they cannot be metal due to corrosion issues. This also adds cost to the final product.

Weatherability: Both polyethylene as well as FRP materials have excellent weatherability properties when properly designed. This is due to the excellent UV (ultra violet) inhibitors and oxidation inhibitors compounded into the material by the resin manufacturers. Both materials will perform well under very harsh environmental conditions. One benefit of polyethylene over FRP is that black polyethylene chemical storage tanks offer better UV protection than just about any other type of aboveground storage tank because of the carbon black used in the black polyethylene resin -- the most efficient of the UV protectant additives. Carbon black works as an absorber and therefore extends the life of the UV inhibitor in the resin. This gives the polyethylene chemical storage tank greater propensity for long and useful life. Quality Assurance/Manufacturing Reliability: Producing a high quality product that meets the design intent of the end user is a goal all successful manufacturers strive for. This is seen in their quality assurance practices and procedures, and how they interact with the customers needs and requirements. This is true for both FRP and plastic tank manufacturers. The FRP manufacturing process is conceptually simple, especially for hand/gun lay-up operations. However, it is quite difficult to maintain tight quality standards when using these lay-up manufacturing methods. The manufacturing of the FRP tanks is improved by the use of filament winding a much more automated and reliable manufacturing method. However, even with filament wounding the number of variables in FRP manufacture (resin, additives, fiberglass type, fiberglass sizing, etc.) are vastly more complicated than with PE rotomolding. Note that, because of the relatively long manufacturing times required to filament wind a tank with integral ends (that is with the ends of the tank wound onto the tank body), a common practice is to wind the cylindrical body and attach the ends afterwards. The ends would typically be made by had lay-up. This procedure results in undesirable seams. Rotomolding has far fewer variables, which results in better quality monitoring and control. We appreciate your time and hope that we have given you a little insight into why we believe our products are the best solution for your chemical storage requirements. If we can be of further assistance or if you would like us to visit your facility in the near future, please do not hesitate to contact us.

HDPE VS HDXLPE TANK:

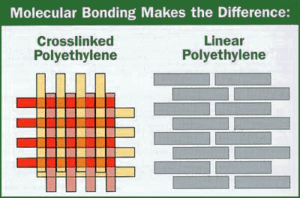

The polymer produced from ethylene monomer is called polyethylene. Many ethylene molecules joined together in presence of a catalyst or initiator to form a polyethylene molecules. The arrangement of ethylene molecules along the main chain is governed by catalyst system used & this determines the property of the PE. If the side chains are very long & highly branched the density of PE will be lower whereas if the side chains are smaller & have regular pattern density will be higher. The polyethylene are classified according to the relative degree of branching (side chain formation) in their molecular structures, which can be controlled with selective catalysts. Low-density polyethylene (LDPE) has more extensive branching, resulting in a less compact molecular structure. High-density polyethylene (HDPE) has minimal branching, which makes it more rigid and less permeable than LDPE. Linear low-density polyethylene (LLDPE) combines the toughness of low-density polyethylene with the rigidity of high-density polyethylene. Cross-linked high-density polyethylene (XLPE) is a form of high-density polyethylene, wherein the individual molecular chains are bonded to each other (using heat, plus chemicals or radiation) to form a three-dimensional polymer of extremely high molecular weight. This structure provides superior stress crack resistance and improves the toughness, stiffness and chemical resistance of HDPE. XLPE is a superior material for molding very large storage tanks, as well as tanks that will be used in high performance applications.

Because of crosslinked molecules, HDXLPE has following advantages compared to linear polyethylene:

- 10 - 20 times the environmental stress crack resistance

- 10 times the molecular weight

- 3-5 times the impact and tensile strength

The four most important factors of high-density linear tanks and cross-linked tanks include:

- Environmental stress crack resistance/notch sensitivity

- Long-term hydrostatic strength

- Toughness and Durability

- Abrasion resistance

- Useful Life

In all four of these areas, factual testing and measurements show cross-linked resins are more durable than linear resins.

The implications of these differences are most obvious when testing the two plastics. When linear polyethylene fails, it can fail catastrophically, because the linear polymer chains tend to “unzip.” In some cases, the entire tank comes undone, and a small leak becomes a chemical spill. All of the stored product could be lost, and the cleanup can be considerable.

On the other hand, cross-linked polyethylene might develop a small pinhole or tear, but the chances of a catastrophic failure is extremely low. You aren’t likely to lose all of your stored chemical if a leak develops, and the cost of cleanup and replacement in most cases is significantly less expensive. The risk to your employees and the environment can be drastically reduced, as well.

In most cases cross-linked polyethylene offers longer useful life in the same application as linear polyethylene. As we stated earlier they are both chemically inert materials. However, because XLPE has a significantly longer life and less financial impact in case of failure, the total useful life of cross-linked polyethylene is significantly better for your bottom line.

M S Tanks Vs PE ( HDXLPE/HDPE) TANKS:

PE tanks have following advantages over metal tanks

- High Strength to weight ratio

- Higher corrosion & chemical resistance

- Virtually maintenance free, no replacement of rubber lining.

- Seamless one-piece design

- Light in weight

- Higher Performance Properties

- Increased Flexibility for Ease of Installation

- Long Life

Mild steel tanks are normally used in the mining industry to store sulfuric acid. If you’re storing a concentration of 98 percent sulfuric acid, your steel tank can perform for many years. However, once the concentration is diluted below 93 percent, sulfuric acid becomes corrosive to steel and your chemical tank’s life expectancy can be significantly compromised.

XLPE tanks can dependably store sulfuric acid at many concentration levels. XLPE's molecular bonding and thick tank wall, provides the necessary structural strength that can more than handle the chemical’s heavy weight. This is especially critical in the bottom third of the tank sidewall, where the highest hoop stress levels are concentrated.

Stainless Steel Tanks Vs. XLPE Polyethylene Tanks:

Stainless steel storage tanks are the traditional choice for breweries, clean-in-place applications, and caustic soda storage. But business-savvy organizations are realizing the benefits of using crosslinked polyethylene storage tanks.

For businesses that are looking to increase profits and scale to the next level, XLPE tanks provide four important advantages:

- Initial cost—On average, polyethylene tanks cost a fraction of what a comparable stainless steel tank costs.

- Longevity—Crosslinked polyethylene tanks are built for longer useful life and have very little maintenance associated with them.

- Seamless- Crosslinked polyethylene tanks are seamless, homogenous tank systems. Stainless steel tanks are welded. A 6000 gallon stainless steel tank can have up 70 yards of welded seams.

- Delivery time—An XLPE tank can typically be ordered and delivered within three to four weeks. A stainless steel tank requires 20 weeks or more for delivery.

Breweries

Traditionally, stainless steel or other metal tanks have been used for every part of brewery operations, from storing the materials to making beer. For small-batch, fast-growing craft brewery operations, polyethylene tanks are the ideal choice to help you scale quickly and respond to market demands. As the craft brewery grows, XLPE tanks can be manufactured and delivered quickly, are cost-effective and available in a variety of sizes.

Clean-in-place Applications

Stainless steel tanks are popular for clean-in-place applications as well. High purity acids and cleaning agents are often needed to clean beverage or food grade equipment to ensure quality and prevent bacterial growth. Our XLPE and specialty food and beverage grade fittings give you a customized clean-in-place storage solution.

Caustic Soda Storage

Sodium hydroxide (NaOH), also known as caustic soda or lye, is a strong chemical base. Its corrosive and slippery nature makes it tricky to store, especially if you need to keep it in liquid form.

Many facilities use stainless steel tanks to store caustic soda. The steel walls are resistant to corrosion, the tanks can be kept outdoors, and heating kits are easy to apply. However, steel tanks cost two to three times more than necessary, and they don’t provide better performance than XLPE tanks.

- Lower initial costs—XLPE tanks are much more cost effective to that of steel tanks.

- Smaller footprint—Our double-wall system eliminates the need for a large concrete berm.

- Lower long-term costs—No concrete berm means less maintenance or repair over the life of your storage system.

- Conservation of lost chemical—If a leak occurs, the double-wall system contains any leaked chemical, preventing loss.

- Seamless -Crosslinked polyethylene tanks have no seams. They are molded as a one piece tank with no weldments like steel tanks.